Tüm ürünler

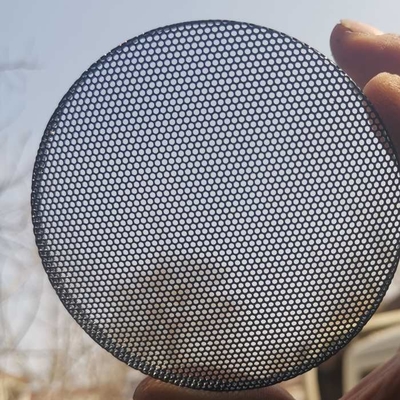

0.1-10mm 1/6 Paslanmaz Çelik Hoparlör Izgara Kapağı Radyo Parçaları Için Kazınmış Delikli Metal Izgara

Ücretsiz numune ve kuponlar için bana ulaşın.

Naber:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Herhangi bir endişeniz varsa, 24 saat çevrimiçi yardım sağlıyoruz.

xÜrün ayrıntıları

| Ürün adı | kazınmış metal ızgara | Malzemeler | paslanmaz çelik, demir, vb |

|---|---|---|---|

| delik şekli | yuvarlak, altıgen delik | Plaka Kalınlığı | 0.1-10MM |

| Filtre oranı | 80-1000um | teknik | dağlama, delikli |

| Yüzey İşlem | Elektrostatik toz boyalı | Özellik | Korozyon Direnci |

| Başvuru | hoparlör ızgarası, mikrofon ağı | Sertifika | ISO9001:2008 |

| Vurgulamak | 10mm Paslanmaz Çelik Hoparlör Izgarası,Paslanmaz Çelik Hoparlör Izgarası Kazınmış Delikli,10mm metal hoparlör ızgarası |

||

Ürün Açıklaması

1/6 Paslanmaz Çelik Hoparlör Izgarası Kapağı Radyo Parçaları İçin Kazınmış Delikli Metal Izgara

Bitirme Tipleri

Metal kaplama, nihai ürünün görünümünde ve dayanıklılığında önemli bir fark yaratabilecek zorlu bir görevdir.En iyi sonuçlar için, son işlem hizmetlerimize güvenmenizi öneririz.

Birçok tür sunuyoruz:

eloksal

Eloksal, birçok metalin yüzeyinde doğal olarak oluşan oksidasyonun kalınlığını arttırmak için kullanılan elektrolitik bir işlemdir.Tipik olarak alüminyum ile kullanılan anotlama, sert, korozyona dayanıklı bir yüzey oluşturmak için alüminyum oksidin doğal özelliklerinden yararlanır.Eloksallı alüminyum, çekici bir metalik parlaklığa sahiptir ve şeffaf veya çeşitli renklerde boyanmış olabilir.

Vernik (Eloksal)

Şeffaf Eloksal, boya veya pigment kullanılmadan alüminyum metal üzerinde ince bir alüminyum oksit kaplama tabakası oluşturan bir işlemdir.

E-kaplama

E-kaplama, bir boya veya cila kaplamayı biriktirmek için bir elektro boyama veya elektroforetik cilalama işlemidir.

elektro galvaniz

En yaygın galvanizleme yöntemi, çinko alaşımının elektrokimyasal biriktirilmesidir.Bu işlem nispeten ince bir galvaniz tabakası oluşturduğundan, dış mekan uygulamalarında en iyi korozyon direncini sağlamak için genellikle boyama önerilir.

Sıcak daldırma galvanizleme

Parça erimiş bir çinko banyosundan geçirilerek elektrogalv ile karşılaştırıldığında biraz daha yüksek bir maliyetle çok daha kalın bir çinko kaplaması sağlanır.Sıcak daldırma galvanizleme, yüzeyde karakteristik bir kristalleşme deseni veya "pul" oluşturur.

boya tutacağı

Ek korozyon koruması ve boya yapışmasını iyileştirmek için bir fosfat banyosuna batırılmış galvanizli çelik.

boya kilidi

Elektronik olarak biriktirilen ve ardından boya veya toz boya kaplamalarının yapışmasını iyileştirmek için kimyasal olarak işlenen çinko kaplamaya sahip galvanizli çelik.

Kaplama

Kaplama, bir metal türünün bir kaplamasını diğerinin yüzeyine yerleştirmek için bir dizi işlemi ifade eder.Kaplama malzemeleri güzellikleri, korozyon dirençleri, sertlikleri ve diğer çeşitli amaçlar için seçilebilir.Örnekler arasında altın, gümüş, krom, çinko, kalay, kadmiyum ve diğerleri bulunur.Kaplama teknikleri de değişiklik gösterir ve hem galvanik kaplama hem de elektriksiz yöntemleri içerir.Projeniz için doğru kaplama malzemesini ve yöntemini tartışmak için bizimle iletişime geçin.

Toz kaplama

Toz Boya, polyester, poliüretan veya epoksi gibi kuru, toz haline getirilmiş bir malzemenin uygulanması için elektrostatik bir işlemdir.Parça daha sonra malzemeyi birlikte akıtmak ve son bitişi oluşturmak için ısıyla sertleştirilir.Toz boya genellikle boyadan daha kalın ve daha dayanıklıdır, ancak projeye bağlı olarak maliyet biraz daha yüksek olabilir.Geniş bir renk seçeneği mevcuttur.Büyük levhalar ve bobinler, oluklu parçalar, bitmiş bileşenler ve hatta özel tasarımlar – Hassas Delme, kaplamanın malzeme için uygun olduğunu belirlediğimiz sürece, delikli parçaya hemen hemen her türlü kaplamayı uygulayabilir.Bitirme fikirlerinizi ve sorularınızı tartışmak için bizimle iletişime geçin.

Şartname:

| Ürün adı | Hoparlör Izgarası Plaka Kapağı |

| Malzemeler | Paslanmaz çelik |

| Delik Şekli | yuvarlak, altıgen, kare vb. |

| Kalınlık | 0,02-0,5 mm |

| Filtre Oranı | 80-1000um |

| teknik | gravür |

| Yüzey İşlem | PVC kaplı |

| Özellik | Hassas parçalar, bileşenler, aksesuarlar. |

| Başvuru | Taşınabilir Müzik Mini Hoparlör, Cihaz, Otomobil, Bina, Sermaye ekipmanı, Enerji, Enstrümantasyon, Tıbbi cihaz, Telekomünikasyon |

| Sertifikasyon | ISO |

![]()

![]()

Önerilen Ürünler